Traceable characterisation of nanostructured devices

Short Name: TReND, Project Number: NEW01

Characterising nano-layered structures

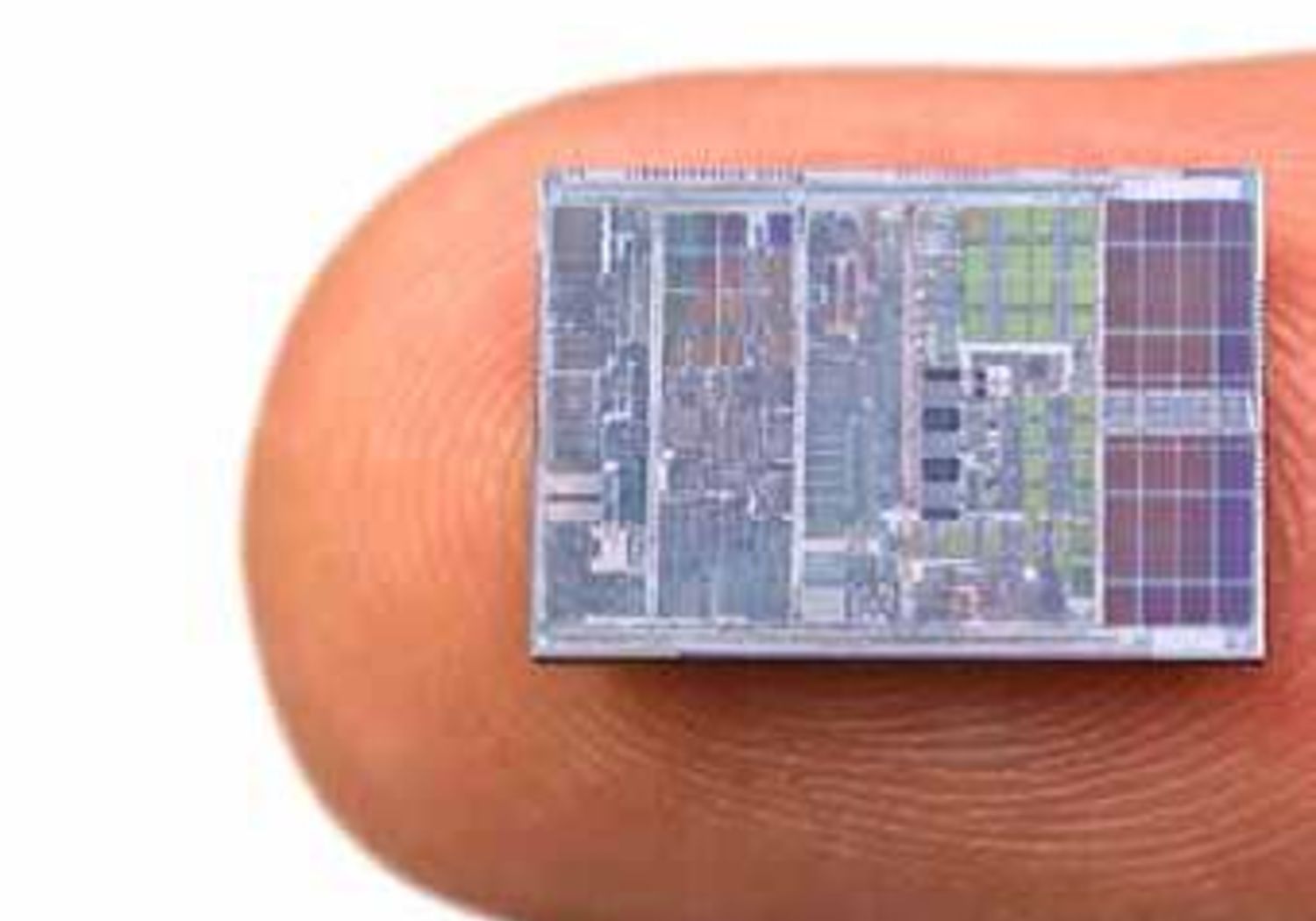

A revolution is occurring in the world of micro- and nano-electronics in terms of miniaturisation, power consumption and processing speed based on new organic materials and multi-layer films. Novel inorganic semiconductor materials and new 3D structures are replacing traditional silicon devices requiring new characterisation methods to facilitate their use in tomorrow’s electronics.

The EMRP project Traceable characterisation of nanostructured devices (TReND) developed robust methods for characterising inorganic nanolayers and sub-surface features for semiconducting materials.

The project:

- Optimised and validated non-destructive x-ray analysis methods for characterising and chemical depth-profiling of traditional inorganic nanolayers such as silicon films. These new analysis techniques are important for achieving greater semiconductor miniaturisation.

- Derived a ‘universal equation’ relating argon cluster beam parameters to the ions it generates, important for 3D nanoscale chemical imaging of organic electronic materials using mass spectrometry. This was subsequently used in a different project to optimise the argon cluster ion beam for a novel 3D OrbiSIMS instrument.

- Developed the metrology for a subsequent EMPIR project to develop an ISO standard for organic depth profiling.

- Demonstrated high resolution 2D mapping of local electrical and photo-electrical properties in organic semiconductor nanostructures using photoconductive atomic force microscopy (PC-AFM).

- Developed a visualisation tool to extract 3D nano-electrical information from 2D mapping data to enable future development of new direct 3D measurement methods.

In silicon based semiconductors, miniaturisation is creating higher demands for a more detailed understanding of deposition processes, and reaction mechanisms in manufacturing processes. To address this, the project optimised non-destructive x-ray analysis techniques for accurately determining changes in chemical composition with depth. Through a rigorous evaluation of grazing-incidence x-ray fluorescence it is now possible to verify calibration standards used for in-line nano-film deposition quality control, where previously few were available.

The project’s ‘universal equation’ has been applied to beam control in a revolutionary new instrument, the 3D OrbiSIMS developed in a collaboration between the pharmaceutical company GlaxoSmithKline, mass spectrometry company Thermo Fisher Scientific, the University of Nottingham and TReND project partners NPL and ION-TOF GmbH, an innovative instrument manufacturer for surface analysis mass spectrometers. Marketed as the 3D OrbiSIMS by ION-TOF, the instrument has the highest simultaneous spatial and mass resolving power achieved to date. This is important for accurately determine complex sub-surface organic nanolayer chemistry which has uses in both biomedicine and electronics. A follow on EMPIR project An International Standard for Reliable Chemical Depth Profiling of Organic Materials is preparing TReND developments for incorporation into an ISO standard for organic depth profiling. Once issued the ISO standard will increase the reliability of novel organic layer analyses important for greater uptake of organic materials into new applications.

EMPIR projects 15SIB09 3DNano, 15SIP02 ISOChemDepth and 17SIP07 Adlab-Xmet build on this work.

Journal of Physical Chemistry B

Surface and Interface Analysis

J. Phys. Chem. C

pss(a) - ALTECH Proc

Journal of Physical Chemistry B

International Journal of Mass Spectrometry

Physical Review B

Journal of Physical Chemistry (B)

Journal of the American Society of Mass Spectrometry

Optics Express

Journal of Materials Chemistry C

Nanotechnology

The Journal of Physical Chemistry C

Journal of Physical Chemistry

Journal of Vacuum Science & Technology