Advanced 3D chemical metrology for innovative technologies

Short Name: 3DMetChemIT, Project Number: 14IND01

Supporting manufacturing through improved measurements at the nanoscale level

Prior to this project there was a need for improved 3D chemical imaging driven by demands from consumers for innovation in high value-added manufacturing. In response industry increasingly turned to using 3D architectures, additive manufacturing and an expanding library of materials. This included devices based on organic materials, such as smart optical films, advanced coatings, and inorganic nano-layered, high-density 3D devices.

In many technologies the interface between organic and inorganic materials caused severe measurement issues. Various techniques offered the potential for improved 3D chemical analysis but had unresolved measurement issues preventing their use.

Secondary ion mass spectrometry (SIMS) measures material removed from a sample using a time-of-flight mass analyser (ToF-SIMS) but lacked resolving power to distinguish different chemical groups with nearly the same mass and was ‘blind’ to a sample’s surface features.

Another technique, Atom probe tomography (APT) utilises a laser and a nanoscale-sized tip to remove individual atoms from a sample and 3D reconstructions are generated based on the time for these to reach a detector. APT lacked standardisation and reconstructions often suffered from severe inaccuracies.

A third technique, reference-free grazing incidence x-ray fluorescence (GIXRF), relied on the knowledge of the fundamental atomic parameters of the material under investigation and lacked the reference materials required to model all the effects a sample can generate.

This project addressed these issues, developing new metrology for accurate, quantitative measurements of chemistry at the nanoscale level.

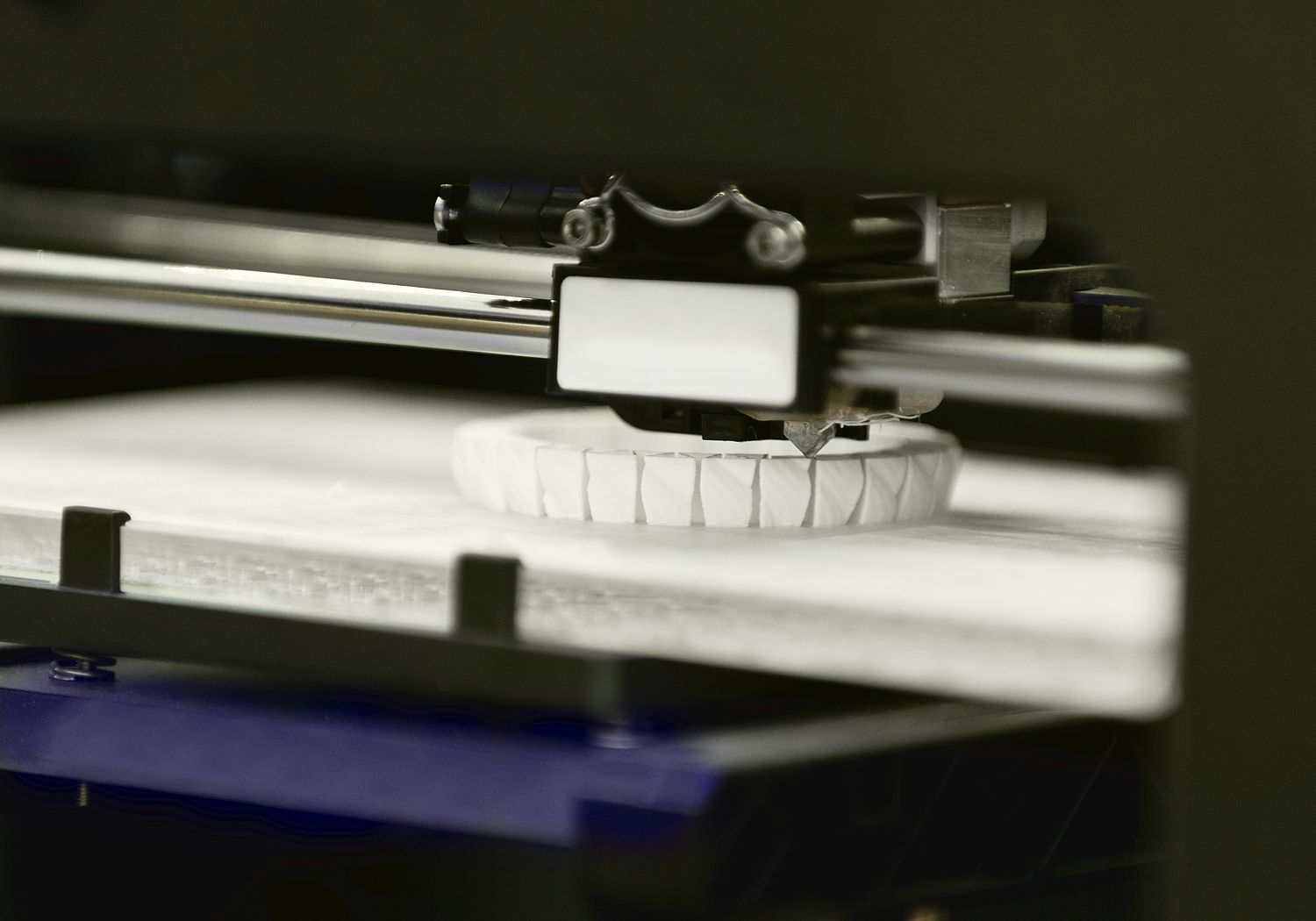

A novel spectrometer was characterised, the 3D OrbiSIMS, combining a ToF-SIMS instrument with an Orbitrap mass analyser. The instrument both analyses the composition of a sample and maps its 3D surface features, with a 10 to 15-fold improvement in mass resolving power and an increase in mass resolution from 10 000 to greater than 240,000.

Key parameters contributing to uncertainty in APT analysis were identified and a new ion beam-based method created tips with increased site-specificity. APT quantification studies demonstrated the ability to make accurate, reproducible measurements on materials important in high value manufacturing such as gallium nitride or silicon doped with boron or germanium.

Three nanoscale reference materials incorporating organic and inorganic materials were fabricated and characterised with a suite of dimensional methods. The traceability of GIXRF was then established using these and results incorporated into a new computational tool, Xraytrace, containing an improved model for X-rays’ interactions with matter.

During the project lifetime 106 conference and poster presentations and a number of workshops were organised to disseminate results to relevant stakeholders, including the 11th DACH FIB and 79th IUVSTA Workshops. Results also inputted into a new work item and a documentary standard for ISO TC 201. The fundamental Parameters for Ni were taken up by two x-ray fluorescence instrumentation vendors and the 3D OrbiSIMS has now been commercialised by ION-TOF.

The improved measurements developed will underpin manufacture in a range of industries developing innovative, high value-added products containing organic/inorganic layers and interfaces which will, in turn, help satisfy consumer demand.

Coordinator: Rasmus Havelund, NPL

For more information, please contact the EURAMET Management Support Unit:

Phone: +44 20 8943 6666

E-mail: empir.msu@euramet.org

Journal of The American Society for Mass Spectrometry

Physical Review A

Journal of Vacuum Science & Technology B, Nanotechnology and Microelectronics: Materials, Processing, Measurement, and Phenomena

Nanoscale

Ultramicroscopy

physica status solidi (a)

Nanotechnology

The Journal of Physical Chemistry C

The Journal of Physical Chemistry C

Nanoscale Research Letters