Large Volume Metrology Applications

Short Name: LaVA, Project Number: 17IND03

Improving large-scale dimensional measurements for manufacturing

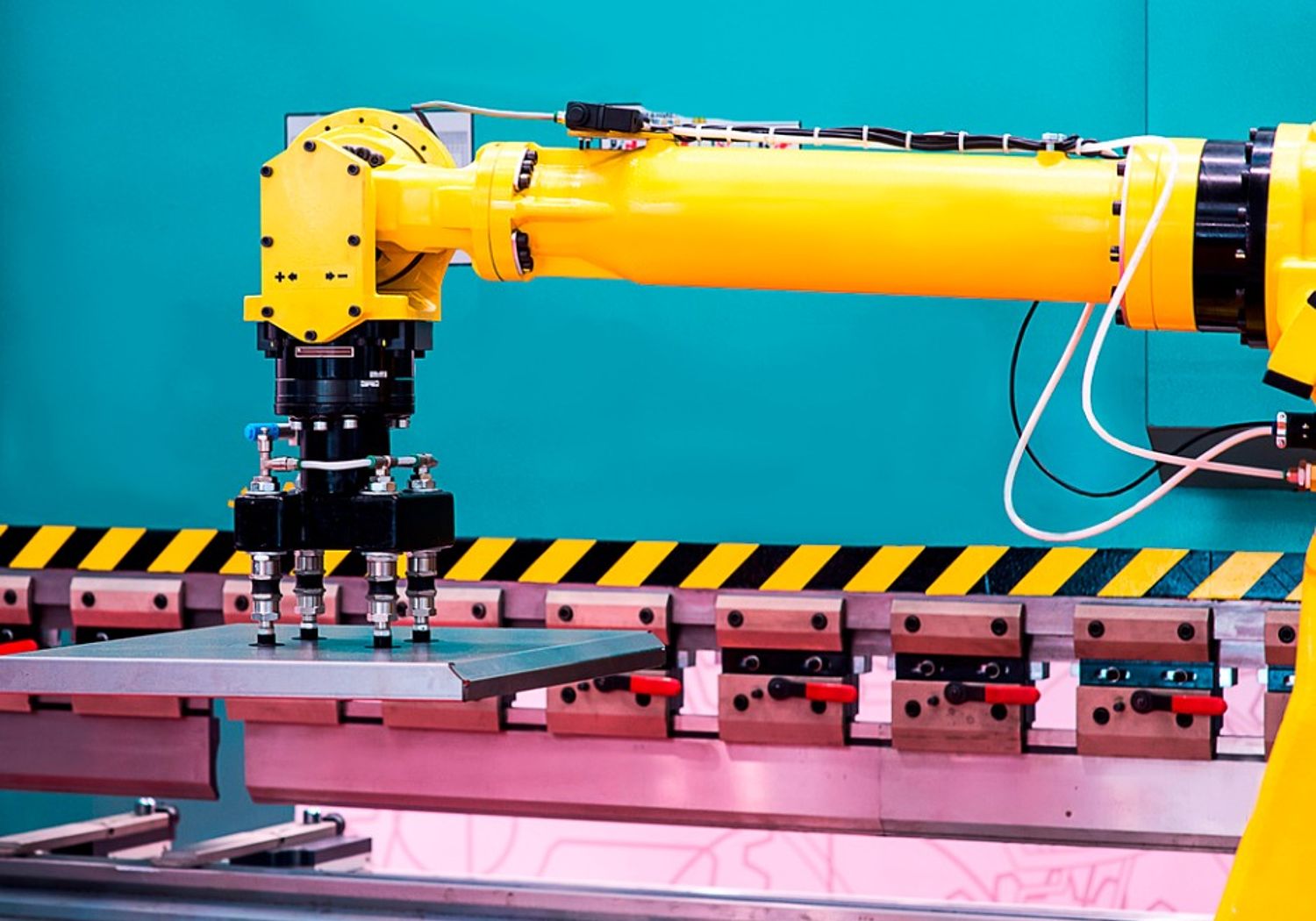

In sectors such as the aerospace and automotive industries, large volume components are manufactured, modified and assembled to create complex products.

For the machine tools, industrial robots and inspection systems employed, various factors limit the accuracy of some laser-based spatial positioning systems; cheaper multi-camera systems are available but offer less accuracy.

Effective response to device data requires a digitally networked production line: such in-line operations for manufacturing and inspection would create more efficient factories of the future.

This project has addressed the industrial need for more accurate large volume coordinate measurements.

A demonstration laser-based position measurement system will exploit improved gas cell data and a new correction method for air refractive index variation.

For multi-camera systems, calibration techniques will be made traceable to National Metrology Institute standards for greater accuracy. The project has also demonstrated the production efficiencies achievable with in-line component inspection.

To encourage industry uptake, results will feed into guides and support for the updating of international standards.

EMPIR project 20IND02 DynaMITE builds on this work.

Precision Engineering

Optics Letters

Optics and Lasers in Engineering

Conference IEEE EFTF IFCS 2021

Review of Scientific Instruments

Precision Engineering

Multimodal Sensing: Technologies and Applications

CIRP Annals

21st Czech-Polish-Slovak Optical Conference on Wave and Quantum Aspects of Contemporary Optics