Please type a search term (at least two characters)

News

Large volume metrology EMPIR project helps industry with recovery from COVID-19

Project addresses the need for more accurate large volume coordinate measurements

As part of its recovery from the COVID-19 pandemic, the aviation industry is currently looking for cost savings and manufacturing efficiency, through the use of better and more accurate automation in manufacturing, targeting weight reduction in aircraft through less shimming, and faster validation of new designs at the testing stage. As airliners sit empty in storage, airlines are re-evaluating future orders against a backdrop of fundamental change to passenger numbers and route capacity. For aerospace manufacturing to respond rapidly to changing demand requires efficient, adaptable manufacturing, reduced development costs and flexible automation - all requiring reliable and accurate metrology.

The ability of factories to operate without humans present has the potential to assist the recovery of industry and provide resilience for the economy in case of further lockdowns. However, this automation in manufacturing depends on reliable metrology to deliver accuracy in machining, positioning and alignment during assembly when there is nobody present, or when having to adapt quickly to a new process, using existing manufacturing and metrology assets.

EMPIR project Large Volume Metrology Applications (17IND03, LaVA) is targeting aspects of automotive, aerospace and Industry 4.0 in order to improve the accuracy of manufacturing and support the transition to the Factory of the Future.

In particular, the project consortium is looking at:

- Aerospace, where the target is weight reduction and the consequential fuel efficiency, lower emissions and lower costs for next generation aircraft.

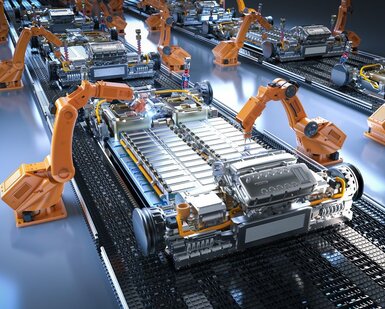

- Automotive and Industry 4.0 (the ‘fourth industrial revolution’), where the consortium seek to provide the metrology that will allow robots to work more accurately, to track autonomously guided vehicles with improved precision in factory volumes to enable increased automation.

These issues are of great importance as Europe recovers from the effects of the global COVID-19 pandemic.

Project Coordinator Andrew Lewis from NPL said

‘As we see the devastating effects of the COVID-19 pandemic in the high value manufacturing industries, we look towards Industry 4.0, with its promises of smart machines, and production facilities that can operate autonomously without human intervention, to offer resilience against future pandemics and assist in sustained recovery from the events of 2020.

Yet we realise that such human-independent systems can only be achieved with the availability of more accurate, ubiquitous metrology. This is why the LaVA project is targeting delivery of factory-wide metrology networks (like GPS/GNSS but working indoors to tens of micrometres accuracy), as well as in situ error compensation of large machine tools, and models for fully cooperative cyber-physical systems such as machine tools, laser scanners, laser trackers and robots. Our stakeholders view these outputs as being integral to their future manufacturing capability.’

This EMPIR project is co-funded by the European Union's Horizon 2020 research and innovation programme and the EMPIR Participating States.

Want to hear more about EURAMET?

Sign up for EURAMET newsletters and other information

Follow us on LinkedIn and Twitter

Carbon dioxide, released from man-made activities, is lowering the pH of the Earth’s oceans, and impacting the health of marine organisms worldwide more

Supporting automated and reconfigurable manufacturing systems more

Working with external project Cool White to test and suggest improvements on the locally available white paints more

The project FutureEnergy has provided new calibration services for ultra-high voltages and a good practice guide on Lightning Impulse dividers more

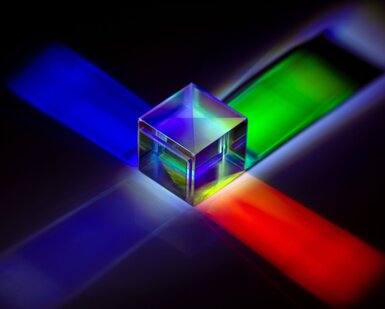

For many of the 5000 photonics companies in Europe a precise knowledge of a material’s optical properties is vital for industrial competitiveness more