Traceable quantitative surface chemical analysis for industrial applications

Short Name: SurfChem, Project Number: IND15

Understanding chemical reactions at surfaces: Improving the speed and efficiency of industrial processes

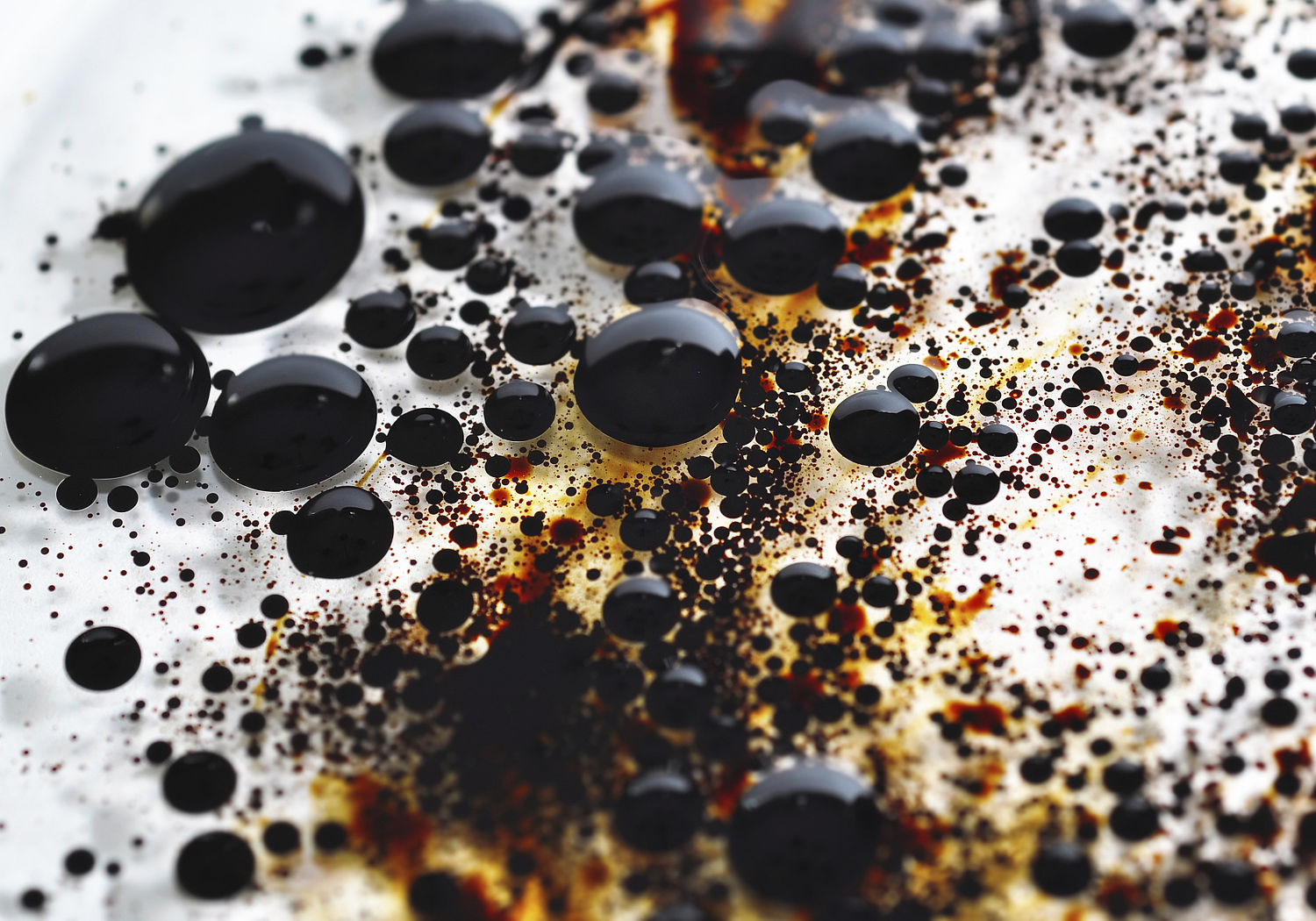

Surface chemical analysis is important to the development and manufacture of a wide range of products. It is a key element in microelectronics, bonding and corrosion for aerospace and transport applications, and also in life sciences for protein adhesion and toxicity for body implants and drug delivery systems. In these fields, the functionality of surfaces, thin films and the interfaces between materials plays an important role in product performance and functionality. The chemical composition of surfaces and interfaces, at the atomic level, is usually very different from that of the bulk material and is often key to the material behaviour and performance. Therefore, understanding chemical composition and structure at surfaces is key to new product development and manufacturing quality control.

This project addressed the need to improve the measurement performance of analytical instrumentation for surface analysis. The project focused on improving the accuracy of key spectroscopic techniques for surface analysis, such as X-ray photoelectron spectroscopy (XPS), secondary ion mass spectrometry (SIMS) and electron probe micro-analysis (EPMA), by developing certified reference materials for instrument calibration and methods to improve the capability of the various techniques. The project developed:

- A universal certified reference material for quantitative analysis by EPMA using EDS (energy-dispersive spectrometry), enabling a traceability chain for detector efficiency. This enables energy dispersive spectrometers to be calibrated to ISO 15632:2012 with only one measurement.

- Certified reference materials for quantitative chemical in-depth analysis of layered organic materials and 2D test structures for the determination of the field of view (FOV) of surface analytical instruments.

- A new diagnostic method based on valid liposome labelling of tissue and imaging time-of-flight (ToF) SIMS analysis and traceable fluorescence measurements for biodiagnostic device platforms.

- Metrology for new, fast, non-destructive quantitative methods of surface chemical analysis by optical, mass spectroscopic and scanning probe techniques for industrial in-line quality control.

European instrumentation manufacturers are using the certified reference materials to validate and optimise the performance of their products and the results have been presented to the relevant ISO committees. A number of new ISO work item proposals are in development that will lead to new or revised standards, thus ensuring the wider use of the improved measurement methods.

Coordinator: Wolfgang Unger

For more information, please contact the EURAMET Management Support Unit:

Phone: +44 20 8943 6666

E-mail: empir.msu@euramet.org

- EMRP Industry theme impact case studies

Surface and Interface Analysis

Analytical Chemistry

Surface and Interface Analysis