Non-destructive surface measurements

Challenge

Many companies are developing products that require a detailed understanding of surface chemistry, such as new catalytic exhaust systems to reduce car emissions, and new coatings to improve optical and functional properties of microelectronics.

Such innovations need very precise non-destructive measurement techniques to study materials or check for surface contamination. Catalyst development for example requires chemical analysis measurements throughout the process to understand how tweaking properties affects functionality.

A suitable technique is Electron Probe Micro Analysis (EPMA) by Energy Dispersive X-Ray Spectroscopy (EDS). EPMA bombards a surface with electrons, which causes surface atoms to emit X-rays. Every atom emits different characteristic X-ray lines, creating a unique fingerprint. EDS measures these X-ray lines and identifies which atoms are present, without causing any changes to the surface. These technologies are widely used – a study of the ISO technical committee “Microbeam analysis” estimated 40 million of samples are analysed annually using EDS and similar techniques.

Until now EDS techniques have lacked traceable reference materials and users have had to rely on in house verification. Universal reference materials certified to a high degree of accuracy and traceable to the SI will improve the cost effectiveness, accuracy and provide greater confidence in EDS use.

Solution

The EMRP Project Traceable Quantitative Surface Chemical Analysis for Industrial Applications has developed new certified reference materials (CRMs) for EDS with well-defined surface chemistries, composition, and structure. These enable EDS users to verify their measurements against universally agreed standards.

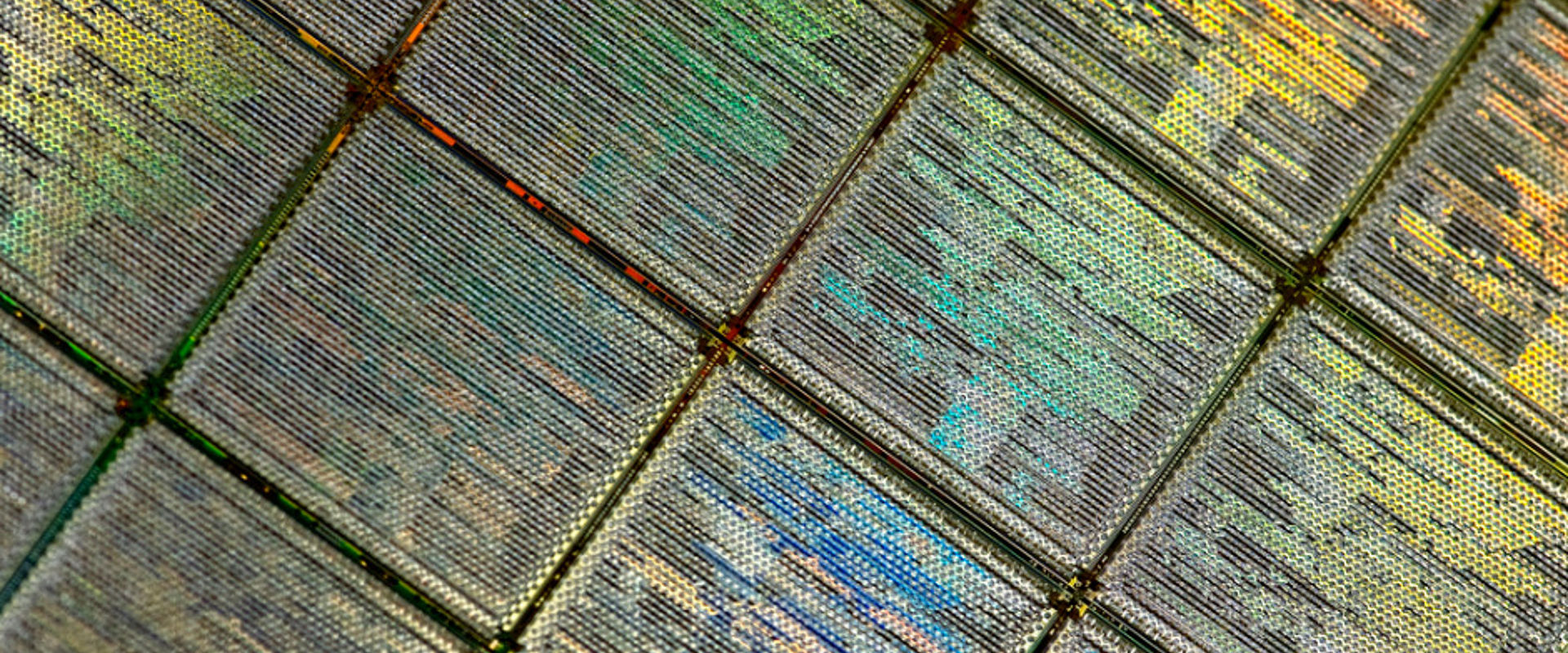

The CRM is a silicon wafer containing four pure elements, enabling EDS to be characterised for a broad range of different chemical species. Each element’s spectra was rigorously measured using a range of different devices, providing very accurate data to define values for its unique elemental fingerprint. The project certified these values, creating a new universal reference material, which is traceable to the SI and can be used to accurately calibrate EDS instruments.

Impact

The reference material has now been taken up by EDS manufacturers, including project partner Bruker Nano Analytics, which has developed a new improved instrument as a result of the project.

Bruker has now tested its instruments at much higher levels of accuracy than were previously possible and identified opportunities for improvement. This has enabled Bruker to develop a new more accurate XFlash© 6 silicon drift detector series.

The improved accuracy of new and existing instruments gives greater confidence in performance, and is proving a valuable selling point helping Bruker stay competitive and preserve its market share. The new instrument will help Bruker’s customers in the semiconductor, automotive, steel and mining industries to improve R&D and quality assurance for new cutting edge products and chemicals.

- Category

- EMRP,

- Industry,