Metrology for airborne molecular contamination in manufacturing environments

Short Name: MetAMC, Project Number: IND63

Monitoring for cleanroom air quality

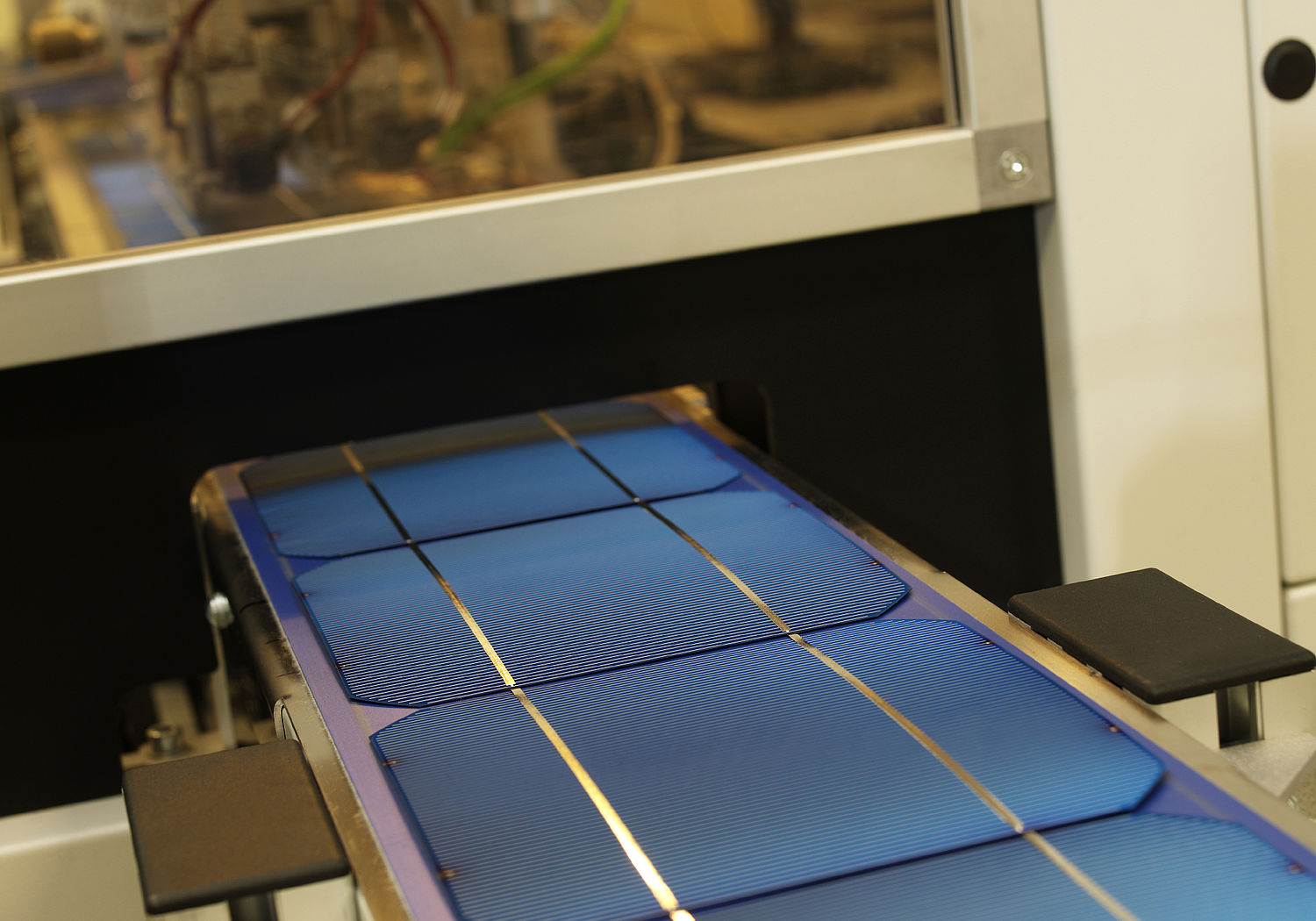

Semiconductors, photovoltaic devices, and nanotechnologies are all advanced technologies that rely on cleanroom production facilities. The European semiconductor market alone is valued at 286 billion euro and employs over 600,000 people. Staying competitive relies on optimising production processes, where small changes have huge financial implications.

Cleanroom production involves chemical processes that create small features and interfaces, but if these chemicals leave traces of contamination in the air this can damage subsequent production stages, leading to faulty parts and rejected batches. Optimal production requires strict air quality control to accurately and rapidly detect traces of process contamination from key airborne molecular contaminants such as ammonia and hydrogen fluoride.

The EMRP project Metrology for airborne molecular contamination in manufacturing environments developed advanced optical instruments for measuring trace amounts of the most critical airborne contaminants, and reference materials to accurately calibrate them. The instruments enable reliable contaminant detection at the parts-per-billion (ppb) level and are suitable for cleanroom use.

The project developed:

- Spectrometry instruments for reliably and rapidly detecting ammonia and hydrogen fluoride at ppb levels in cleanroom air.

- A prototype NICE-OHMS spectrometer; an advanced, analytical instrument with sub-ppb detection capabilities for cleanroom contaminants.

- A method for extending gas chromatography for the monitoring of airborne molecular contamination at trace levels.

- New dynamic reference standards for selected contaminants present at trace levels in cleanrooms, to improve monitoring instrument calibration.

- Best practice guidance on achieving accurate air contamination monitoring, based on determining the most appropriate usage of monitors and investigating materials used in system pipework to ensure reliable sampling.

As a result of this project, industries reliant on the rapid identification of trace contamination in air can now have greater confidence in installed monitoring systems. The knowledge gained from the project has contributed to revisions of ISO standards on the preparation and calibration of gas mixtures using dynamic generation methods, and the NICE-OHMS spectrometer is being licensed for further commercialisation. Other project developments are being incorporated into new airborne contamination monitoring products by the manufacturers Optoseven Oy and HC Photonics.

The project’s advanced air monitoring technology for detecting trace contamination in cleanrooms is now available for industrial use and has the potential to significantly reduce costs whilst increasing the speed of contamination detection. Improving cleanroom air quality will help to increase production efficiency by decreasing yield losses. This will help advanced European manufacturing industries such as electronics by aiding their competiveness in the global market place.

EMPIR project 17IND09 MetAMCII builds on this work.

Applied Physics B

IET Science, Measurement & Technology

XXI IMEKO World Congress “Measurement in Research and Industry” August 30 - September 4, 2015, Prague, Czech Republic

Imaging and Applied Optics 2016

Optics Letters

Applied Physics Letters

Applied Physics B

International Journal of Environmental Analytical Chemistry

5th IMEKO TC19 Symposium on Environmental Instrumentation and Measurements 2014

International Congress of Metrology (CIM) 2015, Proceedings