Keeping cleanrooms clean

Challenge

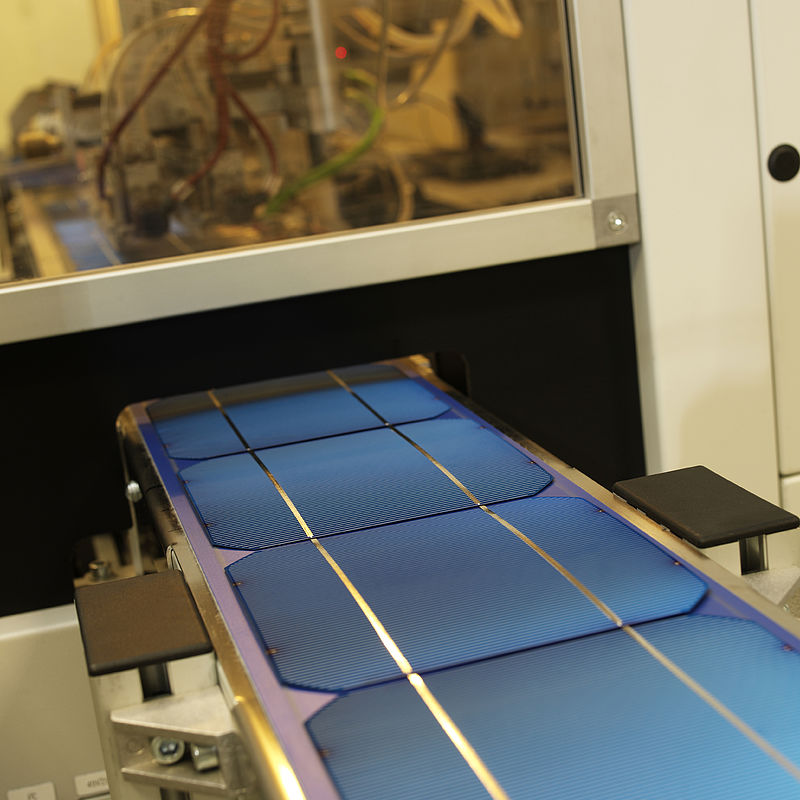

Semiconductor manufacturing requires tiny details to be etched onto silicon wafers using precision chemical processes. These are performed in cleanrooms to avoid contamination. However, chemicals from other stages in the production process, most importantly, ammonia or hydrofluoric acid, can occasionally spill producing traces in the air. Even at very low levels, this chemical contamination can compromise etching, and introduce production faults resulting in lowered process yields.

Most cleanrooms currently employ ion mobility spectrometry to detect specific chemical traces in the air and alert staff, so that remedial action can be taken. It may take time for these monitors to reliably respond to the very tiny chemical traces and this delays production stoppage, leading to wasted components. In many cases the monitors are not able to robustly identify molecules such as acids or bases in a contaminated air stream.

As semiconductors become smaller, miniscule traces of contamination have even greater potential to disrupt production, therefore, new highly sensitive monitoring methods capable of detecting key airborne contaminants in real-time are needed to maintain production efficiency.

Solution

The EMRP project Metrology for airborne molecular contamination in manufacturing environments developed a new instantaneous method for generating low concentration reference gas mixtures used to calibrate highly sensitive cleanroom monitors at close to in-service contamination levels. These gas standards were used to confirm the feasibility of developing optical monitoring techniques for cleanroom use, based on laser spectroscopy principles. Photoacoustic spectroscopy (PAS) was found to have good potential for development into a new type of cleanroom contamination monitor. This technology uses a laser to excite contaminant atoms in the instrument’s measurement cell, then detects and measures the small pressure pulses created as they relax. Each chemical has its own specific response enabling different chemicals to be detected simultaneously using a single instrument.

Impact

As a result of the project, Optoseven Oy, a manufacturer of gas and liquid analyser systems, is now confident that PAS spectroscopy is suitable for cleanroom use. Optoseven has developed a prototype contamination monitoring system for detecting ammonia and hydrofluoric acid in cleanroom air. Optoseven were one of the first users of the improved cleanroom monitoring calibration service resulting from the EMRP project. This enabled them to characterise their prototype and gave their staff the opportunity to gain additional measurement expertise.

To establish the prototype’s suitability for industrial cleanroom operation it was trialled in the VTT cleanroom facility – the largest cleanroom facilities in the Nordic countries. The trials of the PAS contamination analysis system under operating conditions, have demonstrated that Optoseven’s prototype is suitable for real-time analysis of multiple cleanroom contaminants, and that it matches the sensitivity levels needed for semiconductor manufacturing. Optoseven are actively exhibiting the instrument in Asia, the world’s largest region of semiconductor production to promote sales whilst also investigating extending the technology to detect the higher contaminant concentrations encountered in industrial process monitoring.

Laser spectroscopy is an innovative field of new technologies which allows multiple cleanroom contaminants to be detected in real time, giving manufactures immediate notification of problems and reducing the number of parts compromised by contaminated environments. This has the potential to reduce waste and speed time to market for cutting-edge semiconductors and nano-technologies.

- Category

- EMRP,

- Industry,