Standardisation and Dissemination for Measurements of High Performance Barrier Layers

Short Name: TF-Plastic, Project Number: 14SIP04

Supporting emerging technologies through improved standards on moisture-control materials

By 2025 the global markets for graphene and organic electronics are predicted to be 220 million and 170 billion USD respectively. Ensuring Europe’s forefront position in these emerging technologies will require both innovation and consumer confidence.

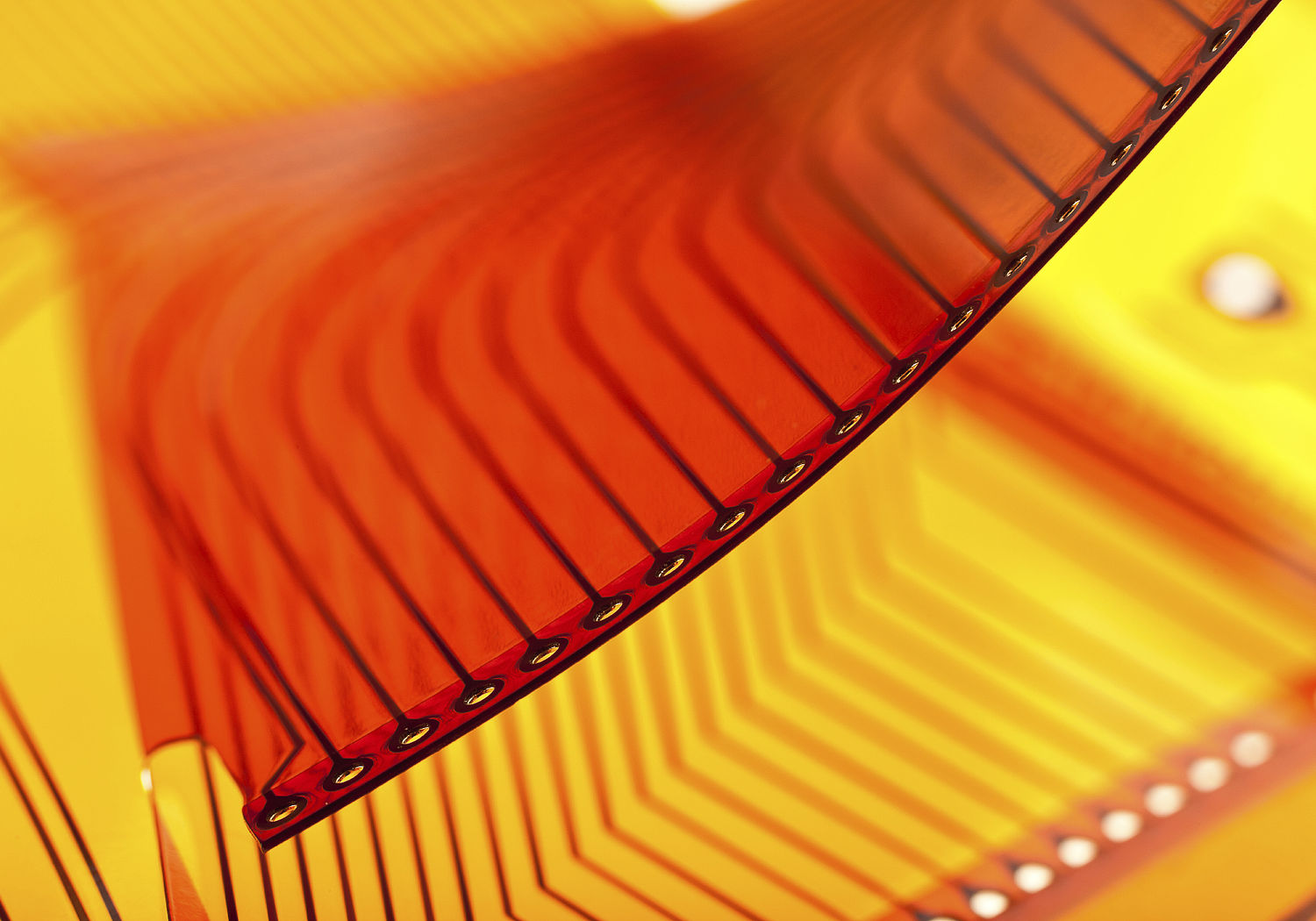

One of the largest factors affecting product lifetime is a high sensitivity to moisture and thus a protective surface or ‘barrier’ layer is applied to these items. An important measurement parameter for this layer is the ‘water vapour transmission rate’ (WVTR) which quantifies the amount of water from the atmosphere passing through the barrier over time. However, the wide variety of techniques and experimental conditions used to determine WVTR has created inconsistencies in reported data that has impacted on the development of barrier materials. WVTR measurements must also be highly sensitive as organic thin-film LEDs require moisture barriers capable of preventing the ingress of even a few micrograms of water per square metre per day. During the EMRP project Metrology for the manufacturing of thin films NPL established a WVTR facility for accurately assessing the permeation rates of barrier layers with traceability to the SI. However, effective dissemination of the methodology developed was challenging during the project’s lifetime as the technology was not sufficiently mature. Now, with barrier materials being used more widely in industry across Europe the need for standardisation providing specific advice to end-users, such as manufactures of electronic displays, ‘roll-able TVs’ or solar cells, on how to correctly conduct WVTR measurements and calibrations is vital.

This project successfully disseminated the knowledge gained in the previous project. Working closely with the Organic Electronics Association, which provides guidance to the organic electronics community, NPL held a stakeholder meeting on standardisation for encapsulation of plastic electronics. Attended by over 30 experts discussions included quality aspects and sensitivities in the measurement of WVTR, new technologies, adhesives, mechanical properties and test architectures. Outputs from this were included into a new work item submitted to the international standard technical committee ISO/TC 61. This item provided best practice guidance on a range of WVTR test conditions and measurements including humidity, temperature, sample preconditioning and the specification of gases and reagents used. A particular focus was on measurements of WVTR below 1 x 10-4 g m2 day-1, where the largest measurement challenges lie and where there is the most pressing requirement from industry to have confidence in measurement comparability. This data has now contributed to a recommendation paper on WTVR that currently acts as an industrial standard in the absence of normative standards. NPL also reviewed the facilities at the Centre for Process Innovation (CPI), providing guidance on the design and development of a WVTR testing facility with traceability to national standards.

By supporting the adoption of new methodology, through the development of new standards, this project will increase product reliability and encourage innovation within the manufacturing industry, essential for Europe’s position on the global field.