Please type a search term (at least two characters)

News

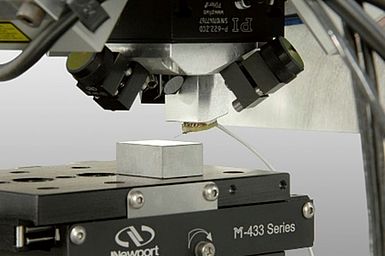

New microprobes for material property measurements successfully machine tested

EMPIR project develops tactile microprobes and guidance for fast and reliable material surface measurements in industry

For the production of materials and coatings used in modern technology, surface quality monitoring is key: high-value manufacturing requires accurate measurement of properties such as roughness, elasticity and contamination. As the demand for precision increases, tactile microprobes used to inspect components need better characterisation.

Completed EMPIR project Multifunctional ultrafast microprobes for on-the-machine measurements (17IND05, MicroProbes) developed tactile microprobes for material surface measurements in industry. Probe tips were developed for improved wear resistance, and their geometries were characterised for better accuracy in various modes of use. By integrating such devices into the manufacturing process, in-line product inspection can be 30 times faster compared with off-line methods. Production-line efficiency and waste reduction through improved quality control therefore delivers direct economic and environmental benefits.

Project achievements include:

- 6 Good Practice Guides published, aiming to support the precision engineering community by improving surface texture and mechanical property measurements.

The 6 Good Practice Guides are:

- Calibration of tip radius of fast microprobes on the machine

- Setting probing force and scanning speed of fast microprobes for non-destructive roughness and microform measurements

- Measurement of liquid lubricant layer thickness using the force-distance curve method with fast microprobes

- Measurement of the thickness of coating layers using the contact resonance technique with fast microprobes

- Measuring the complete geometric map of rolls containing the form and microstructure using fast microprobes

- In-situ wear damage measurement using fast microprobes with integrated feed-unit

- New long slender piezoresistive microprobes with integrated actuator developed. The project developed new piezoresistive microprobes with electro-thermal actuator and diamond tip, which partner GETec Microscopy was one of the first to trial in their AFSEM®. Furthermore, a microprobe with piezoelectric (AlN) actuator capable of sensor actuation for contact-resonance use was designed at the TU of Braunschweig.

- Long piezoresistive microprobes for the first time integrated into a commercially available AFM: A printed circuit board adapter for microprobes to be integrated into a Cypher AFM developed by TUBS in cooperation with PTB, Germany’s National Measurement Institute, was successfully tested by BAM.

- MicroProfiler with integrated feed-unit allows high speed roughness measurements on manufacturing machines: BMT developed a micro profiler prototype with high-speed texture measuring up to 8 mm/s, this development enables users to measure roughness inside manufacturing machines and is being made commercially available.

- Microprobe tested in setup for roll measurement: Large-scale rotors in the paper and steel industry are called rolls. Rolls are reground at regular intervals and dimensional measurements are made throughout the machining process. Deviations from required diameter, form and texture affect the quality of the end product. During the project the comparison of primary profiles measured with stylus instrument and microprobe showed good agreement, considering that there are uncertainties of the exact location of the profile combined with the inhomogeneity of the roughness standard. The development of the commercial version will be continued.

- In situ Microprobe Monitoring of Progressive wear on Alumina. The microprobe successfully measured the evolution of wear damage in a ceramic material.

Project coordinator Uwe Brand from PTB said

‘We just published a paper documenting the obtained critical damping of our microprobes. These damped microprobes will allow measurement speeds beyond 10 mm/s in fast and reliable surface texture and roughness measurements in industry. We are now looking for industrial partners who would like to take up and use the developed technology’.

This EMPIR project is co-funded by the European Union's Horizon 2020 research and innovation programme and the EMPIR Participating States.

Want to hear more about EURAMET?

Supporting automated and reconfigurable manufacturing systems more

Working with external project Cool White to test and suggest improvements on the locally available white paints more

The project FutureEnergy has provided new calibration services for ultra-high voltages and a good practice guide on Lightning Impulse dividers more

For many of the 5000 photonics companies in Europe a precise knowledge of a material’s optical properties is vital for industrial competitiveness more

The project partners publicised the metrological developments for electronic brachytherapy and were able to contribute to several standards more