News

EMPIR project produces new device for magnetic field observation

An EMPIR project has produced a new device that can observe the dynamic magnetic fields created inside steel sheeting during energy production

The project

EMPIR project Metrology of magnetic losses in electrical steel sheets for high-efficiency energy conversion (19ENG06, HEFMAG) has extended the testing methods used to measure power loss due to magnetisation in devices.

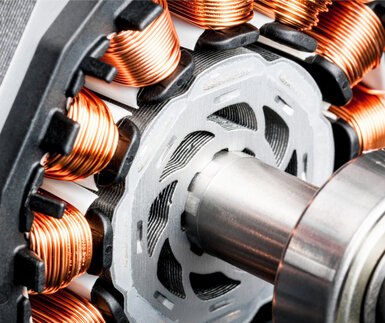

Most industrial electric devices, such as the motors, generators and transformers used in energy production, use steel sheeting in some form. During operation, this steel becomes periodically magnetised and demagnetised, a process which can cause up to 10 % of the total energy produced to be lost. Although standards exist to specify minimum efficiencies for these devices, these standards – and the testing required to implement them – do not consider real-world operational conditions, including high temperatures, high power levels and the influence of microstructures.

The HEFMAG project has improved standard energy tests for use at higher frequencies and power levels and has created new methods for high temperatures, up to 155 °C.

New observation device

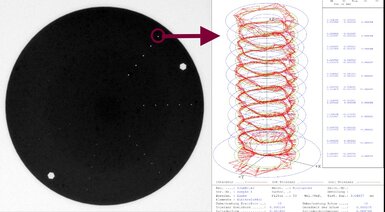

Project partner INNOVENT has developed a new device based on magneto-optical indicator films (MOIF). MOIF are thin, transparent films which can be used to observe the magnetic field of a sample using polarised light. The MOIF device developed by INNOVENT is used to observe how magnetic domains form and change under alternating field conditions within grain-oriented electrical steel – the most common magnetic steel used in energy production. The formation and evolution of these domains is a main source of energy loss and so being able to observe and understand them is key to maximising efficiency.

The new device uses a high frame rate camera (8 kHz at high resolution or up to 19 kHz at lower resolutions) and can make observations under alternating fields with frequencies up to 400 Hz. These specifications make it possible to make continuous observations of magnetic losses within the material at different angles and at varying frequencies.

A second prototype, with similar specifications, has also been installed at PTB, Germany’s National Metrology Institute, and can be used in parallel.

Other achievements

- Paper Published

The project has published “Anisotropy of losses in grain-oriented Fe–Si” in the open-access journal AIP Advances. This paper outlines work by the project on measuring energy losses from grain-oriented steel sheets over a range of frequencies from 1 - 300 Hz. It improves upon previous models and allows for magnetic losses to be understood in terms of angle, polarisation level and frequency.

- Extended accredited measurements

As a result of work completed by HEFMAG, project partner NPL, the UK’s National Metrology Institute, has extended its measurement services. They now offer accredited measurements for specific total loss and apparent power over a larger frequency range with lower uncertainty.

Project coordinator Massimo Pasquale (INRiM, Italy) has said about the project:

“The HEFMAG project partners have already performed an incredible amount of measurements and we are now analysing the data, and interfacing with our industrial and academic stakeholders to maximize the project impact, i.e. providing calibrated samples for measurements in a very wide range of conditions, as required by novel renewable energy and electro-mobility applications. The novel Innovent device, based on indicator films, will also allow a much wider range of users to perform accurate domain observations and improve properties of magnetic steel products.”

This EMPIR project is co-funded by the European Union's Horizon 2020 research and innovation programme and the EMPIR Participating States.

Want to hear more about EURAMET?

Information

- EMPIR,

- Energy,

Developing quantum electric current standards to underpin digital transformation more

Creating a metrological infrastructure to monitor biomethane for use in transportation and gas networks more

Memristive devices that can be used as resistance standard or can be used for computing applications more

Supporting the digital transformation in Europe by monitoring the detail detection sensitivity of iCT measurements more

Validated, SI-traceable reference methods and materials to assess trace elements in discarded goods more