Improving sub-nanometre accuracy

Challenge

Innovations in nanotechnology are producing novel materials with unique properties, such as the functionalised surfaces that are spurring the development of a new generation of electronics. Verifying that these nanoscale innovations perform as designed relies on measuring their features with sub-nanometre accuracy.

Ultra-high-resolution Scanning Electron Microscopy (SEM), Atomic Force Microscopy (AFM) and optical techniques such as confocal microscopy and interferometry are used to assess height changes across surfaces and distances between features with nanometre accuracy. Calibrating these instruments and confirming their performance currently relies on using reference standards with physically machined ridges, but these can only be manufactured with steps down to 6 nm. This is fine for now, but existing machining techniques cannot produce ridges small or precise enough to confirm the further advances in microscope precision that will be available in next generation nano-technologies.

New reference standards are needed based on sub-nanometre length standards to characterise microscopes with this level of precision. Using the fundamental properties of crystals, such as the distance between atoms, could provide reliable measurement standards at this scale. However, constructing such standards requires the development of reliable production and rigorous characterisation methods.

Solution

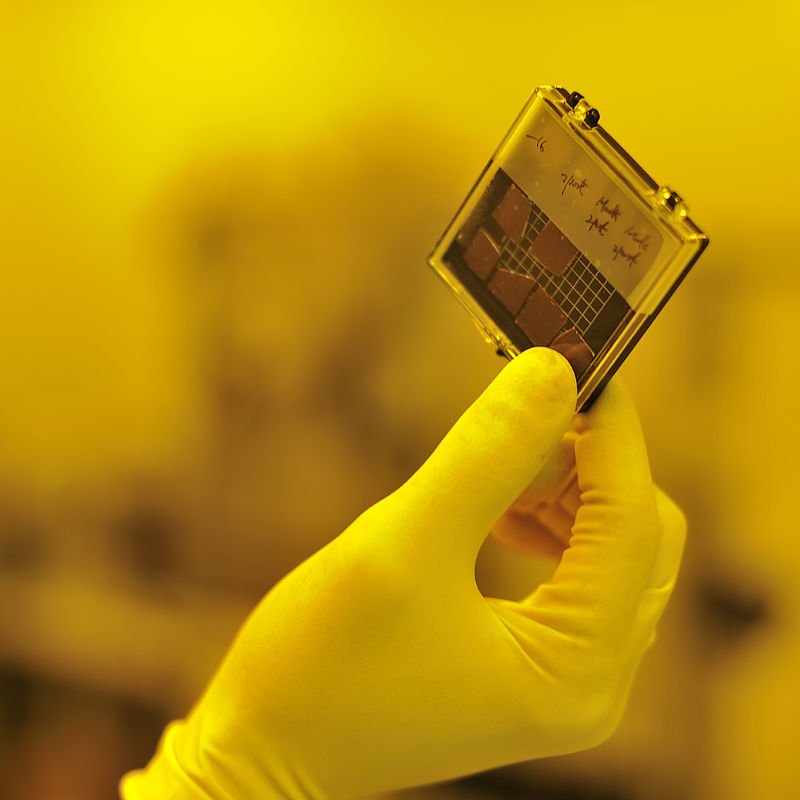

The EMRP project, Crystalline surfaces, self-assembled structures, and nano-origami as length standards in (nano)metrology, investigated different types of materials and assembly methods for creating sub-nanometre structures and prototype dimension standards.

This was achieved by taking advantage of fundamental properties of nature that create regular, predictable crystalline structures. In creating these standards, project researchers focussed on extending the use of low-cost production methods based on technologies routine in the semiconductor industry. By using silicon crystals, and controlling environmental conditions during crystal formation, they created small regular steps of less than 0.3 nm spacing.

The so-called ‘staircase’ standards are 20 times smaller and 10 times more accurate than existing reference standards. These will now undergo evaluation by the international measurement community to confirm their links to SI units, and assess their suitability for industrial use.

Impact

Sensofar, develops high-end optical measurement instruments, and was one of the first users of the project’s novel step height dimension standard. The company used the staircase standard to explore the limits of its current microscopes and to support R&D for new ones.

This will help Sensofar future-proof their business, demonstrating that their products exceed client expectations, whilst also helping them create and validate a new generation of ultrahigh resolution measurement tools for emerging nanotechnologies. Once the staircase standard has been validated for wider industrial use, other instrument manufacturers will also benefit from being able to accurately characterise more precise instruments.

The resulting improvements in sub-nanoscale measurements will support the development of ever smaller innovations in electronics and other nanoscale applications, such as the creation of nanoparticles and carbon nanotubes, which are of great interest to the environmental and health sectors.

- Category

- EMRP,

- SI Broader Scope / Integrated European Metrology,