Faster solar cell product development

Challenge

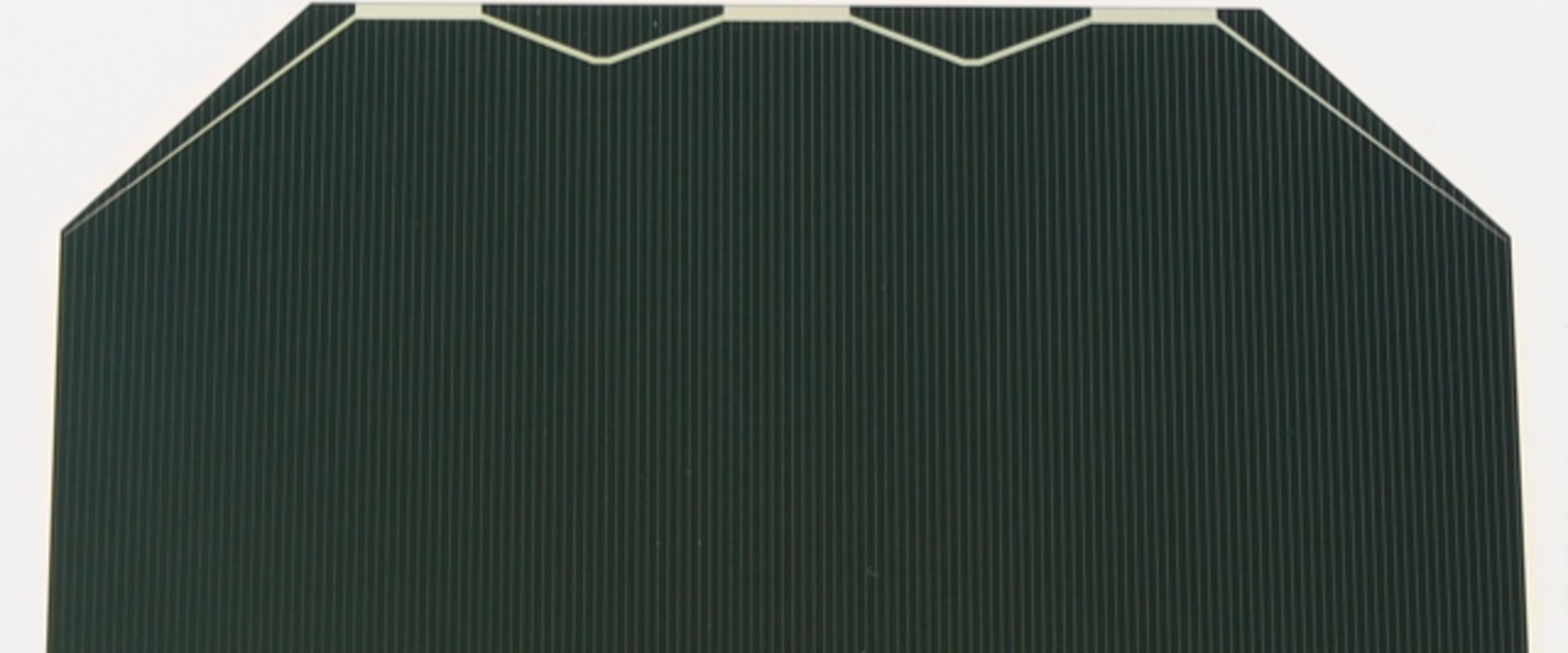

Multi-junction solar cells (MJSC) are made up of layered semiconductors that, together, absorb a wider range of solar energy than silicon alone. Higher energy conversion efficiencies for this type of cells are predicted, that, in time, may enable photovoltaics to become cost-competitive with conventional energy sources. Manufacturing and material advances could lead to breakthroughs, but the process requires precise measurements of cell characteristics. However, development was slowed by an impractical industry-standard calibration method.

MJSC efficiency is measured using solar simulators, that are calibrated using standard solar cells, that, in turn, were calibrated onboard high-altitude balloon flights. This standard had the advantage of removing effects of the atmosphere on incident sunlight but air safety regulations limited flight opportunities, meaning there had only been one flight available between 2005 and 2019.

Measurement of efficiency is critical to MJSC commercialisation, as errors translate in the market to considerable costs from under or over-supply of energy. In a competitive environment where speed to market is essential, a new standard was urgently needed, providing at least the same calibration certainty as for the existing method.

Solution

The EMRP project Metrology for III-V materials based high efficiency multi-junction solar cells applied laboratory-based, differential spectral responsivity (DSR) calibrations, using laser-based spectral measuring methods to establish a ‘synthetic’ multi-junction solar cell calibration standard.

This standard achieved measurement uncertainties comparable to balloon flight calibrations, that could be performed in the laboratory.

Calibration procedures and measurement uncertainty budgets were also included in a good practice guide on multi-junction reference solar cell calibration methods.

Impact

AZUR SPACE, the German manufacturer of high-performance MJSCs for satellite applications, provided solar cell assemblies for use as reference cells for the project. It subsequently contracted project partner PTB to provide ongoing calibration services for its reference solar cells. At the time of writing, this has involved the delivery of four-junction MJSCs on which to perform qualifications and product characterisations, that led to the commercialisation of new cell designs.

Airbus Defence and Space is already a customer and agreed to use AZUR SPACE’s four-junction design to power its Neosat telecommunications satellite scheduled for launch by the European Space Agency before the end of 2021.

AZUR SPACE commented that the new synthetic calibration method has become essential for the photovoltaic industry, especially as safety rules continue to limit opportunities for operating balloon flights.

Since 2007, AZUR SPACE has disseminated its technologies developed for the space market to the terrestrial concentrated photovoltaic market, that is a growing part of its business.

- Category

- Energy,

- EMRP,