Metrology for the manufacturing of thin films

Short Name: Thin Films, Project Number: IND07

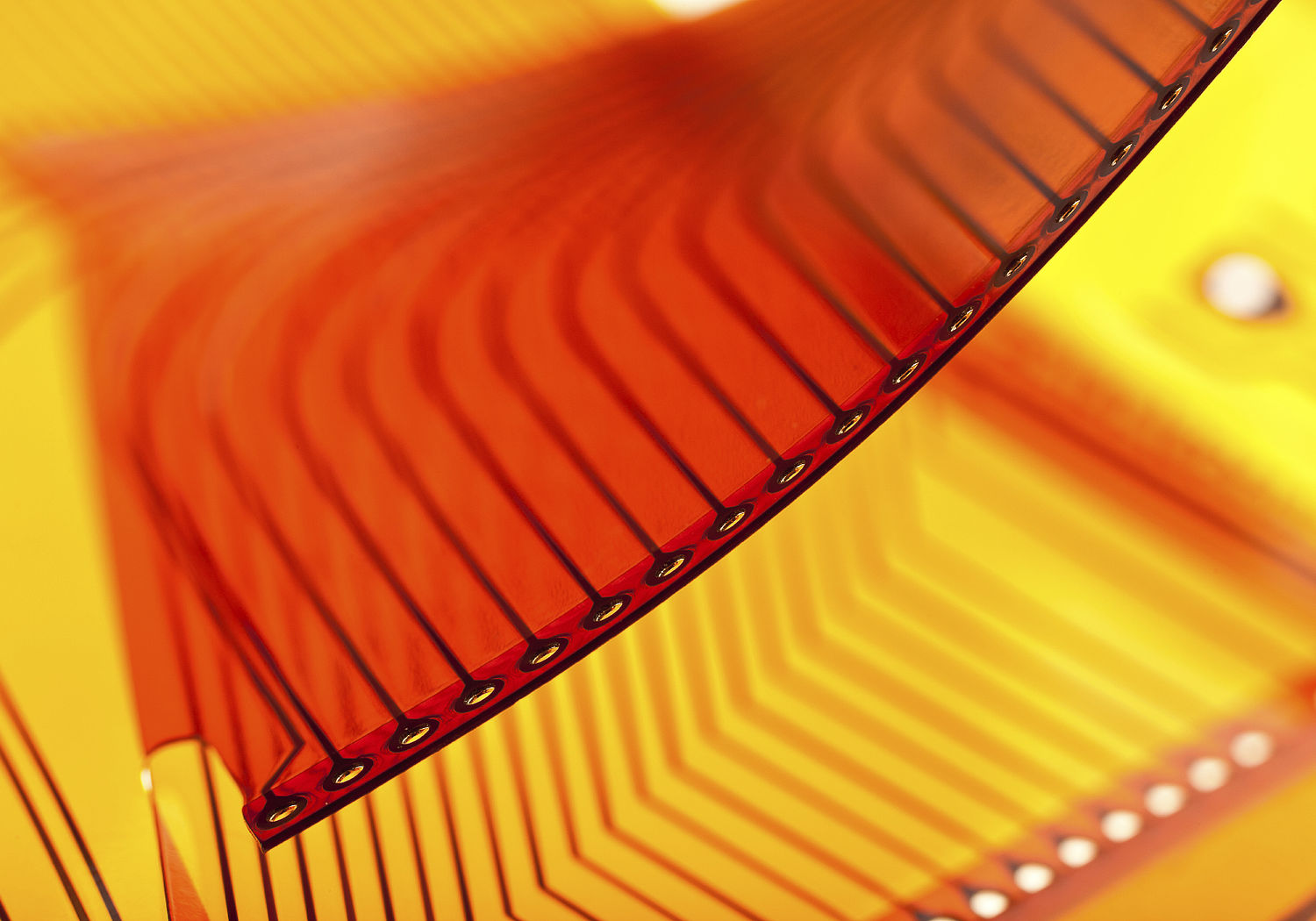

Enabling the development of thin film technology: Helping thin film technologies become a reality

Thin-film materials possess novel properties not found in bulk materials, enabling their use in the production of high-value products in the optoelectronics industry, such as plastic and printed electronics, displays and lighting, solar cells and memory storage devices. A major challenge is controlling consistency in thin-film processing. Production of thin films is limited by a lack of understanding of precisely how changes in the composition and structure of thin-film materials affect properties such as electronic and thermal conductivity.

This project established a pan-European metrology capability providing validated and/or traceable metrology for thin films. The project developed:

- Traceable measurements and validated methods for thin-film properties (thermal transport properties, charge carrier mobility and atomic fundamental parameters) including a novel facility for traceable measurement of thermal conductivity in thin films for temperatures up to 1000 °C and a protocol for charge carrier mobility characterisation of thin-film organic semiconductors that reduces uncertainties from 300 % to 20 %.

- A facility for traceable measurements of water vapour transmission rate through barrier layers that is a significant advance beyond existing methods and provides accuracy at a detection limit below 5 x 10-5 g/m2/day.

- Microstructure characterisation (morphology) by non-destructive and contactless measurements.

- A range of reference materials and transfer standards relevant to the production environment.

- New techniques for measurement of film thickness and optical/optoelectronic properties over large areas for in-production applications, including a prototype multi-electrode system for photo-electrochemical imaging of thin films and a protocol for accurate photocurrent mapping of challenging third-generation solar cells.

The new calibration samples and methodologies are already in use by manufacturers of instrumentation for thin-film characterisation. This disseminates measurement traceability across the value chain, targeting in particular test laboratories measuring key parameters for the semiconductor industry. Other equipment manufacturers have evaluated prototype calibration samples developed by the project and there is potential for commercial exploitation. Additionally, thin-film manufacturing companies gained insights into how manufacturing steps affect the performance and quality of their thin-film products.

EMPIR projects 14SIP04 TF-Plastic and 14SIP05 TF-STANDARD build on this work.

- EMRP Industry theme impact case studies

Applied Spectroscopy

Metrologia

Physical Review A

Organic Electronics

Organic Electronics

Journal of Optics

Measurement Science and Technology

Materials Research Society Proceedings

Thin Solid Films

The Journal of Chemical Physics

Applied Physics Letters

Journal of Applied Physics

Advanced Engineering Materials

REVIEW OF SCIENTIFIC INSTRUMENTS