Developing an ISO Technical Specification “Characteristics for a stable ionisation vacuum gauge”

Short Name: ISO Gauge, Project Number: 20SIP01

Bringing standardisation to the field of high and ultra-high vacuum measurements.

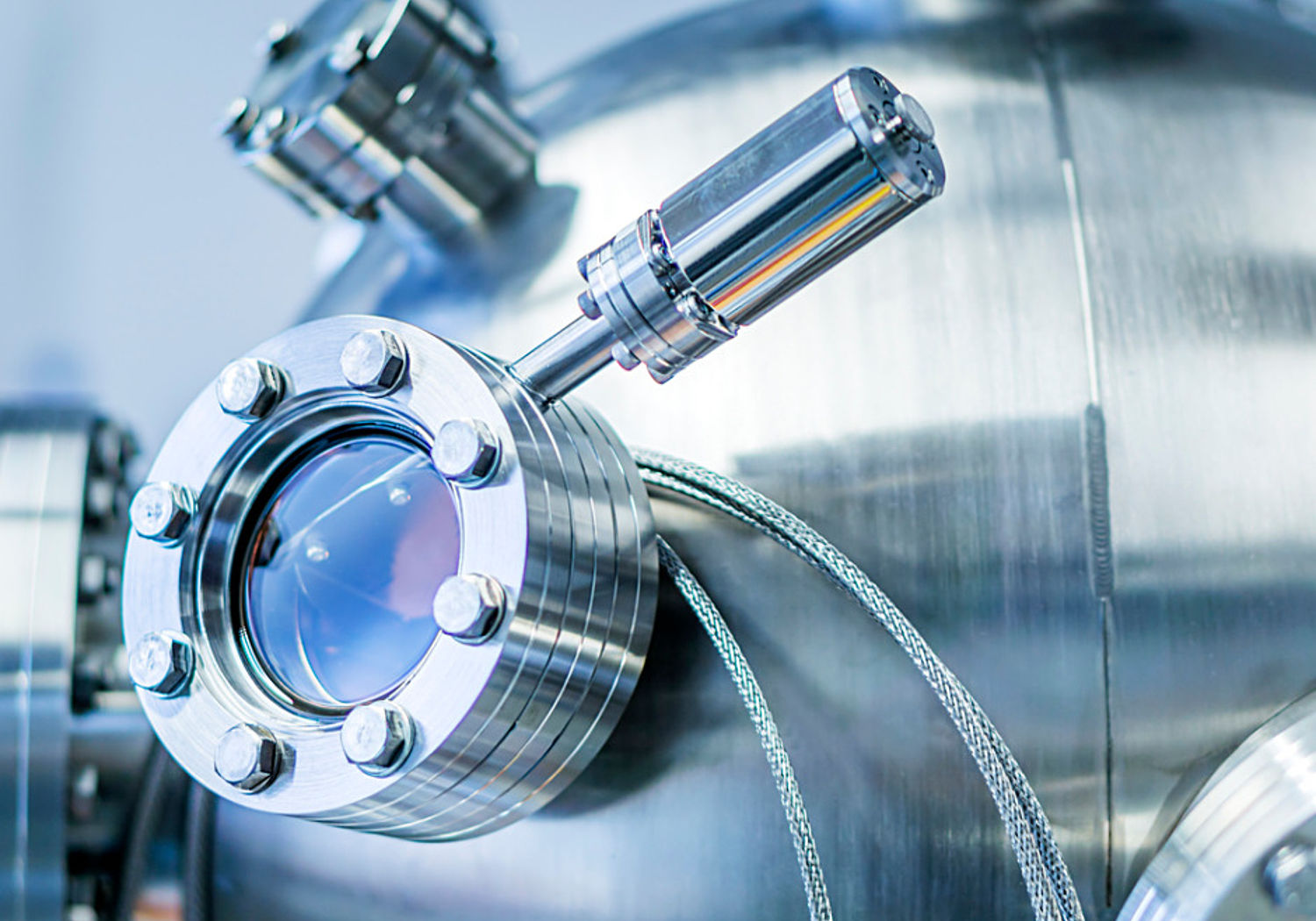

High and ultra-high vacuums are used in scientific fields such as high-energy accelerators, plasma and fusion science, thin films and in industries such as solar cells, optoelectronics and the semiconductor industry. The only way to measure such low pressures is using vacuum ionization gauges. However, all gauge manufacturers produce products that differ in materials, potentials, geometry and relative sensitivity for gasses other than Nitrogen. In addition, all types lack long-term and transportation stability. The EMPIR project Ion Gauge developed a new vacuum gauge design that is accurate, robust, stable and with known relative gas sensitivity factors. However further work was required to bring standardisation to this important field.

This project will address the request from ISO Technical Committee 112 “Vacuum Technology” (ISO TC 112) that these results are implemented into an ISO Technical Specification "Characteristics for a stable ionisation vacuum gauge". Working with ISO TC 112 a draft specification will be cast incorporating the important design characteristics required for a stable ionisation vacuum gauge which will then be incorporated into an ISO Technical Specification. The benefits of the new standard will then be presented to European manufacturers via presentations at conferences.

Uptake by manufacturers will allow them to produce an ionisation vacuum gauge ("ISO gauge") with metrological characteristics independent to its design and traceable to the SI. This will result in an increase in the competitiveness of the European vacuum industry, allow better optimisation in sectors using high and ultra-high vacuums, and give National Metrology Institutes worldwide a reliable transfer gauge for comparison with their primary standards.