Please type a search term (at least two characters)

News

Two EMPIR projects work together to bring measurement to the IIoT

Research from two projects collaborating benefits the Industrial Internet of Things

Consortia working on two separate European Metrology Programme for Innovation and Research (EMPIR) projects have joined forces in order to increase the benefits and impact for industry. The strong collaboration of these projects will help to bring the benefits of traceable measurement to the Industrial Internet of Things (IIoT).

Working together, the two project consortia have:

- formed a joint stakeholder advisory board who inform the project consortium on the needs of industry, academia and standardisation, and give feedback on project outputs such as the most suitable sensors and interfaces for the two projects

- developed a demonstrator to showcase the utilization of the D-SI data model in the communication of measured data using a flexible mulit-agent system framework

- implemented a prototype uncertainty-aware anomaly detection in IoT that uses a Long Short Term Memory network to identify anomal behaviour in uncertain sensor data

- started development of a one-touch calibration of MEMS temperature sensors with output of digital calibration certificates

The two projects that are collaborating are:

Communication and validation of smart data in IoT-networks (17IND02, SmartCom) which is working to define a digital format for the secure transmission and unambiguous interpretation of measurement-related data used in science and technology, the Digital SI and the Digital Calibration Certificates. Wiebke Heeren from PTB, and coordinator of this project, said

‘Our projects perfectly complement each other, for example by enabling to demonstrate the benefit of digitalising measurement and calibration data in the IIoT environment and in return providing real-world requirements to improve the data format definition.’

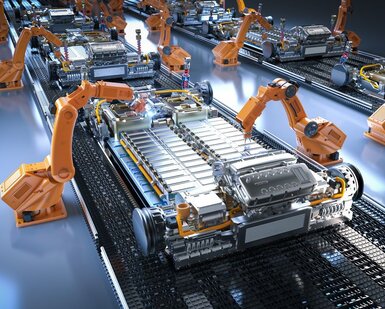

Metrology for the Factory of the Future (17IND12, Met4FoF) is developing sensor network metrology and calibration methods for advanced digital-only industrial sensors, including those with internal pre-processing capabilities. Sascha Eichstädt also from PTB, and coordinator of this project, said

‘With the combination of both projects we are able to cover the whole lifecycle of data in the industrial IoT – from measurements traceable to the SI to the uncertainty-aware machine learning’.

This EMPIR project is co-funded by the European Union's Horizon 2020 research and innovation programme and the EMPIR Participating States.

Want to hear more about EURAMET?

Sign up for EURAMET newsletters and other information

Follow us on LinkedIn and Twitter

Carbon dioxide, released from man-made activities, is lowering the pH of the Earth’s oceans, and impacting the health of marine organisms worldwide more

Supporting automated and reconfigurable manufacturing systems more

Working with external project Cool White to test and suggest improvements on the locally available white paints more

The project FutureEnergy has provided new calibration services for ultra-high voltages and a good practice guide on Lightning Impulse dividers more

For many of the 5000 photonics companies in Europe a precise knowledge of a material’s optical properties is vital for industrial competitiveness more