Please type a search term (at least two characters)

News

EMPIR project develops new ionisation gauge for high vacuum measurement

The new gauge will be made available to calibration laboratories and the research will feed into new ISO standards

The project

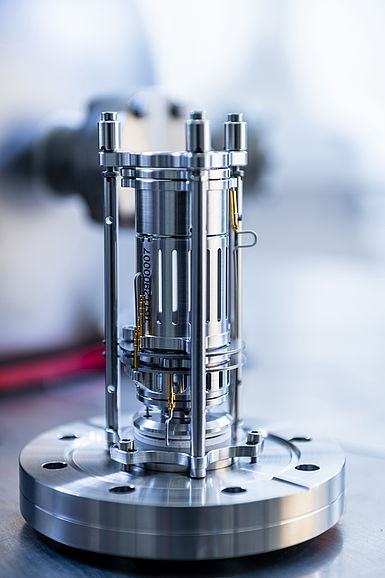

High and ultra-high vacuums are used for cutting edge materials research and in the production of microelectronics. Ionisation gauges are the only method for measuring pressure in such vacuums. Different approaches to constructing ionisation gauges, and the different gasses used for the ionisation process, have led to significant differences in the relative sensitivity factors between them with all lacking long-term stability. The performance of these approaches could be greatly improved by standardisation.

Recently completed EMPIR project Towards a documentary standard for an ionisation vacuum gauge (16NRM05, Ion gauge) worked to specify all relevant parameters for an improved and standardised ionisation gauge. The technical results will inform new documentary ISO standards on ionisation gauges.

Innovative standardised ionisation gauge

The project developed a standardised ionisation gauge that has standard features and performance, meaning it can be used to achieve measurement traceability.

The gauge will provide a reliable reference standard for calibration laboratories and will allow manufacturers of vacuum gauges to produce the gauge by the forthcoming ISO Technical Specification, which will be the subject of a new working group and also a new EMPIR project Developing an ISO Technical Specification "Characteristics for a stable ionisation vacuum gauge" (20SIP01, ISO Gauge).

As a first instrumentation manufacturer INFICON is taking steps to produce the innovative gauge. Since the company aims to offer it together with a compact electrical controller, which requires development, it will take some more time before the set can be offered to customers.

This work found interest at CERN and was presented in an article entitled Vacuum metrology: made to measure in the journal CERN COURIER. This new development will provide greater accuracy to the vacuum market, and to the many industries it supports such as materials researchers and electronics manufacturers.

Project Coordinator Karl Jousten from PTB said that this is the first reliable ionisation vacuum gauge developed so far and it is the first significant development for vacuum metrology since the invention of the spinning rotor gauge in the 1980s.

This EMPIR project is co-funded by the European Union's Horizon 2020 research and innovation programme and the EMPIR Participating States.

Want to hear more about EURAMET?

Sign up for EURAMET newsletters and other information

Follow us on LinkedIn and Twitter

Carbon dioxide, released from man-made activities, is lowering the pH of the Earth’s oceans, and impacting the health of marine organisms worldwide more

Supporting automated and reconfigurable manufacturing systems more

Working with external project Cool White to test and suggest improvements on the locally available white paints more

The project FutureEnergy has provided new calibration services for ultra-high voltages and a good practice guide on Lightning Impulse dividers more

For many of the 5000 photonics companies in Europe a precise knowledge of a material’s optical properties is vital for industrial competitiveness more