Please type a search term (at least two characters)

News

Efficient district heating from new flow models

Understanding how fluids move around pipes - whether in heating systems or in the transport of commodities such as oil and gas - is vital for improving efficiency and safety. But fluid flow in pipes is inconsistent which makes measuring it hard. Better models are needed to understand how bends in pipes influence fluid flow, so that reliable corrections can be made to the flow meters used to make these important measurements.

Challenge

Monitoring how fluids flow through pipes is vital to the efficiency and safety of many systems, from transporting hot water around buildings to transporting oil across continents. Accurately measuring these rates allows for detection of leaks, helps optimise the system for energy efficiency, and is used for correct taxation/billing where the fluid attracts a duty.

Flow meters, which measure this fluid flow, are calibrated before installation on test benches. However once installed in a system, two challenges arise. Firstly, fluid flow characteristics in complex pipe networks such as district heating systems is very different to the ideal conditions used for calibration, as pipe bends cause different fluid flow rate distributions across the diameter of the pipe. Secondly, it is not easy to remove a flow meter for recalibration. These combined problems lead to measurement errors as high as 20%.

A correction factor is applied to the flow meter measurement to offset flow irregularities. This is calculated using flow simulation models, which estimate the effects of pipe direction changes, but current simulation methods involve computationally expensive processes and lack accuracy. Better methods of understanding non-uniform flow rates, would allow us to reliably check and recalibrate flow meters, improve measurements, better understand flow rates, and thereby optimise performance.

Solution

The EMRP project Novel mathematical and statistical approaches to uncertainty evaluation developed new statistical models to better estimate the effect of flow disturbance on meter measurements.

Parameters such as operating pressure, temperature and pipe layout, were measured and input into fluid flow models to generate data sets. These were then used for calculating uncertainties using the Polynomial Chaos approach – a statistical method which allows derivation of statistical quantities for deterministic processes with a specific set of random parameters. This new and faster method provides accurate estimates of system flow rates with related uncertainties using less computer processing capacity and without compromising quality.

Impact

Optolution Messtechnik GmbH, which specialises in calibrating district heating system flow meters, has used models developed in the project to create an effective in-situ flow meter calibration tool.

Optolution has developed a calibration method which measures fluid flow speeds by passing laser beams through the flowing fluid – via an installed optical window in the pipe near the system’s flow gauge - and measuring interference at the crossing point. By moving the beams they can scan flow speeds at different points across the pipe bore and generate the data on which fluid flow speed calculations are performed.

Using adapted versions of the project’s fluid flow rate model, which have been incorporated into their software, Optolution can determine system flow rates under the disturbed flow conditions that installed gauges routinely experience, without interrupting the systems operation. The results their lasers generate are related to the installed gauge’s measurements forming a calibration method for the installed gauge.

The introduction of the model gave Optolution sufficient confidence to apply for accreditation from DAkkS, Germany’s accreditation body for DIN EN ISO/IEC 17025, and enables them to offer a certified calibration service for flow meters. Once granted, Optolution expects to expand their customer base, both in Europe and to countries around the world where district heating systems and also water supply systems are commonplace.

Carbon dioxide, released from man-made activities, is lowering the pH of the Earth’s oceans, and impacting the health of marine organisms worldwide more

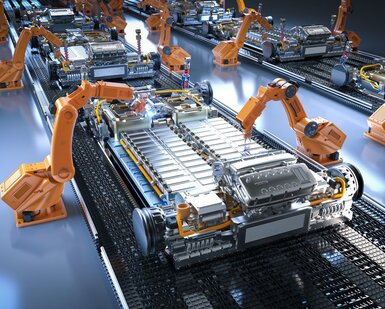

Supporting automated and reconfigurable manufacturing systems more

Working with external project Cool White to test and suggest improvements on the locally available white paints more

The project FutureEnergy has provided new calibration services for ultra-high voltages and a good practice guide on Lightning Impulse dividers more

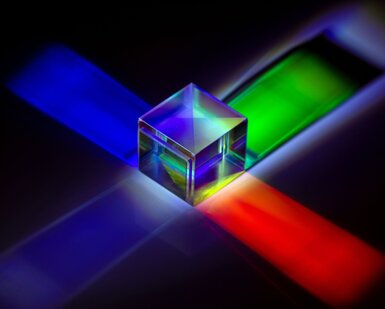

For many of the 5000 photonics companies in Europe a precise knowledge of a material’s optical properties is vital for industrial competitiveness more