Metrology for Advanced Industrial Magnetics

Short Name: MetMags, Project Number: IND08

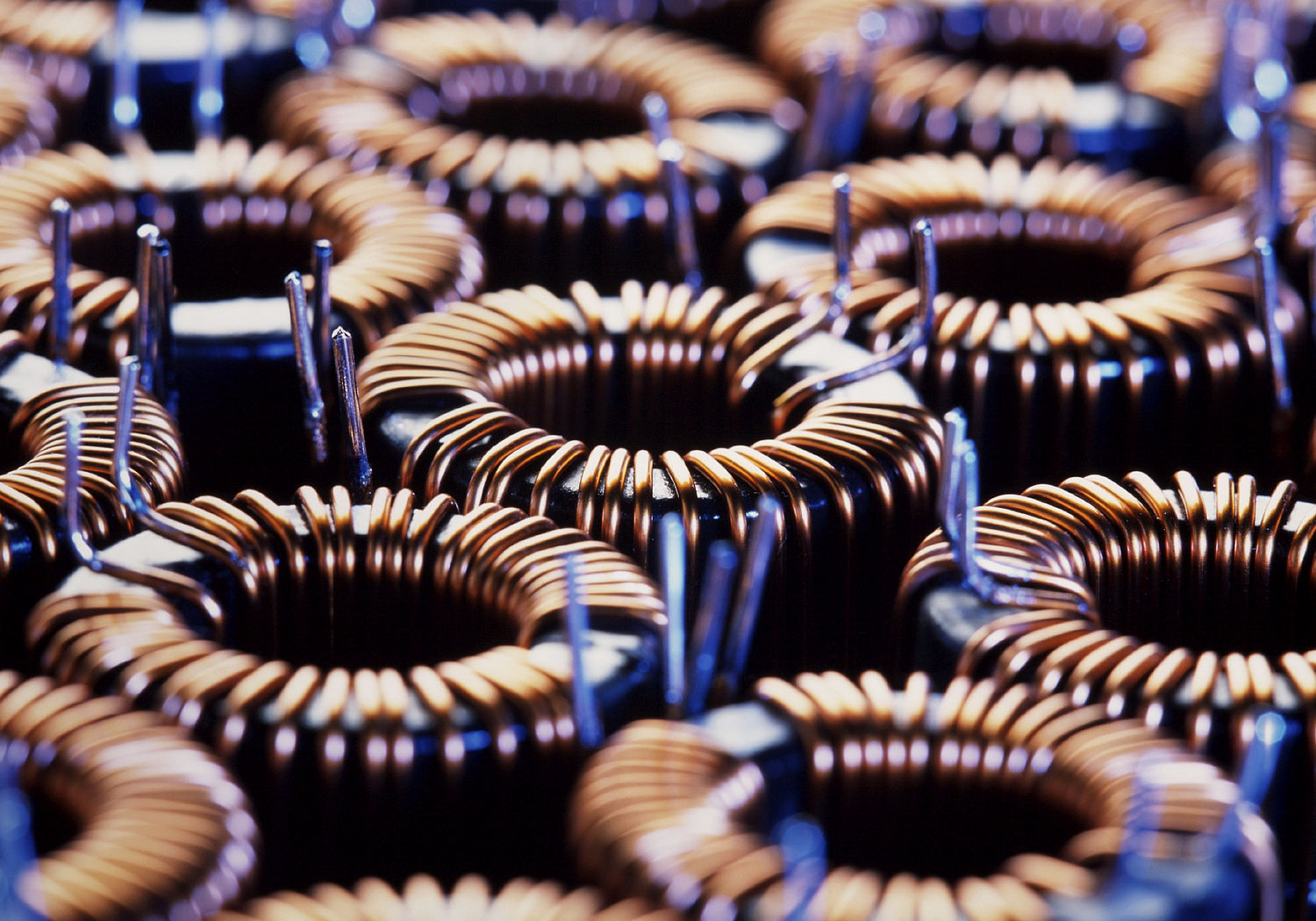

Developing novel magnetic materials: Improving high-resolution electronic measurements

Magnetic sensors are used in industries that require accurate high-resolution data, such as the consumer electronics, ICT and automotive industries. The fast product development in these fields creates an ongoing need for advanced magnetic sensors with significantly-improved specifications in resolution, reliability and operation temperature. An improved understanding of the physical properties of magnetic materials is needed to enable sensor manufacturers to develop advanced anisotropic magnetoresistance (AMR) sensors that are ultra-small, with low noise and high sensitivity, and hence improve electronic measurements leading to more advanced products.

This project developed new calibration facilities, tools and methods to enable the European magnetic sensor industry to develop advanced magnetic sensors and stay competitive in the global market. The project developed:

- Metrological tools and methods for industrial magnetic sensor development including tools for the micromagnetic modelling of micro- and nano-scale magnetic thin films, a metrology system for characterising key parameters of novel magnetic domain wall sensor devices and a new micro-Hall-sensor based method for the calibration of the stray fields of near-field probes for magnetic force microscopy (MFM).

- Metrological in-line tools and methods for sensor production including a method for the fast and non-destructive inductive determination of key material parameters for spin-torque (ST) materials and MFM in variable magnetic fields and under variable applied stress.

- Metrology for sensor testing and calibration including a novel calibration procedure for the calibration of tri-axial Helmholtz coil systems, a portable three-axis superconducting quantum interference device (SQUID) system to determine the magnetic noise vector field behaviour in industrial facilities, and a low magnetic field facility with a magnetic shielding and thermal isolation that provides a magnetically- and thermally-stable environment for noise measurements down to a frequency of 0.1 mHz.

The project team worked closely with sensor manufacturers and users to ensure the adoption of the metrological tools and methods. For example, a world-leading AMR sensor producer has optimised its magnetic manufacturing process using the MFM system. The low magnetic field facility has also been used to measure the magnetic moment of components for the European Space Agency EarthCARE mission. In addition, the new 3D magnetic field calibration systems have been used in precision calibrations for applications in geological exploration.

- EMRP Industry theme impact case studies

Journal of Magnetics

IEEE Transactions on Magnetics

Nanotechnology

Cystals

IEEE TRANSACTIONS ON MAGNETICS

Journal of Applied Physics

Applied Physics Letters

Journal of Applied Physics

IEEE Transactions on Magnetics

IEEE Transactions on Magnetics

Journal of Applied Physics

Journal of Physics D: Applied Physics

IEEE Transactions on Magnetics

Journal of Applied Physics

Journal of Applied Physics

Journal of Applied Physics

Journal of Applied Physics

Physica B - Condensed Matter

Physical Review B84